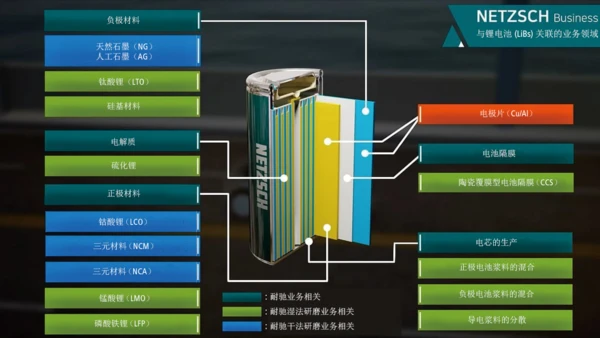

锂电池(LiBs)电芯的主要成分

研磨

有一种正负极材料合成叫做固态工艺。

在该工艺路线中,活性材料是由原材料在适当的工艺炉中通过化学转化生产的。根据所用原料的不同,合成前可能需要对原料进行湿法研磨和干法预磨。

因此,材料越细,混合就越均匀,因此,为了提高电池的效率,材料的解团聚过程非常重要。

研磨

来自外部的冲击应力能量使颗粒产生形变断裂面,如果这个能量超过临界值,则颗粒被破碎。外部能量进入产品内部,形成新的颗粒表面。

解团聚

原始颗粒非常细(微米以下)。然而,它因为静电或干燥过程团聚在一起。解团聚是干法分散工艺,不会形成新的表面积。

工艺解决方案

System Solution

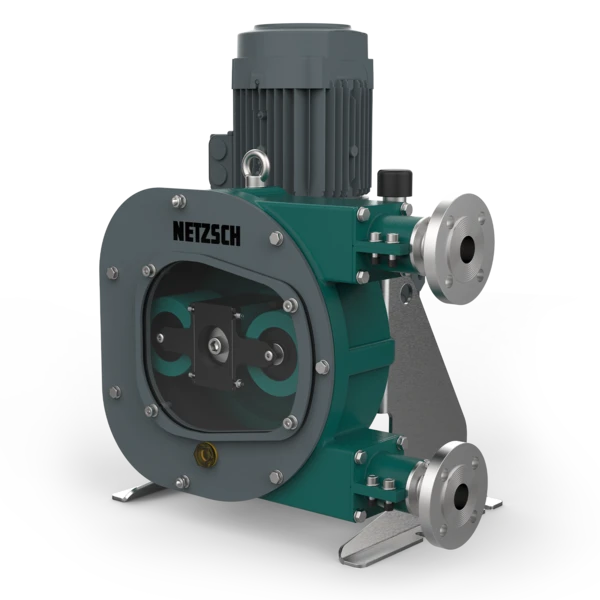

Pumping solutions like NEMO® progressing cavity pumps or PERIPRO peristaltic pumps are the important machines in battery producing lines, that have been used to convey many kinds of glue and battery slurry and so on mediums, as the dosing and metering pumps, mainly application in the battery slurry process and coating procedure.

The axial speed is very small that means low shear rate is applied into the medium, so the results is that the mechanical and chemical characteristics of the medium does not change conserves its viscosity without break any emulsion. When pumping solution is used, pump keep the same volumetric displacement each rotation, the flux volume can be based on the volumetric displacement.

With pumping solution, it is possible to keep linear performance with the rotating speed, the same volumetric displacement each rotation. And, there is no pulsation, continuous uninterrupted flow. For shear sensitive Mediums, low shear factor of all type of pumps, can handly solids particles without damage them, with High solid, high viscosity.

Especially, when producing lithium-ion battery electrode, usually select pumps to dose or meter kinds of slurry for positive pole or negative pole, including solvent series liquid and water series medium.

Analyzing Solution

In the process of making the batteries anode and cathode, the raw material is heat-treated and sintered.

Sintering is the process of heating the mixed raw material and making it into a thermosetting material. For heat treatment and sintering, it is important to understand the thermal properties of the batteries’ raw materials and active materials.

By doing a thermal analysis of active materials, thermal behavior can be identified according to the composition of each active material. For example, when the active materials reacting with active gases such as O2 and H2, the properties of active materials change. To avoid this phenomenon, there is a method of measuring thermal properties with TGA and DSC. The TGA analyzes the changes of mass under the inert gas atmospheres such as N2 and Ar in the Glove box. DSC analyzes the thermal properties of active materials by preventing the active gas reaction by sealing with a high-pressure sample fan. In addition, the gas from thermal analysis can also be analyzed by coupling GC-MS or QMS to the TGA or STA. In addition, DIL or TMA can be utilized to evaluate the sintering of the material.