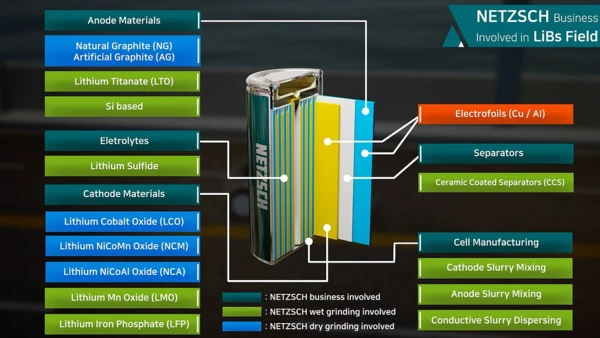

Main components of LiBs cell

Grinding

One option for the synthesis of cathode and anode materials is the so-called solid-state process.

In this process route, the active material is created from the raw materials through a chemical transformation in suitable furnaces. Depending on the raw materials used, a wet grinding stage with dry pre-grinding processes can be required for the raw materials prior to the synthesis.

Therefore, the finer the material, the more evenly mixed, so how finely the material is de-agglomerated is important in order to increase the efficiency of the battery.

Grinding

The impacted stress energy from external is stored by elastic deformation in the particles. If it exceeds a critical value, then it is broken. The external energy into the product is changed to make a new surface.

De-Agglomeration

The primary particles are very fine(under micron). However, it is aggregated by electrostatic force or drying process. De-agglomeration process is dry dispersing process and it doesn’t make a new surface.

Process Solution

System Solution

Pumping solutions like NEMO® progressing cavity pumps or PERIPRO peristaltic pumps are the important machines in battery producing lines, that have been used to convey many kinds of glue and battery slurry and so on mediums, as the dosing and metering pumps, mainly application in the battery slurry process and coating procedure.

The axial speed is very small that means low shear rate is applied into the medium, so the results is that the mechanical and chemical characteristics of the medium does not change conserves its viscosity without break any emulsion. When pumping solution is used, pump keep the same volumetric displacement each rotation, the flux volume can be based on the volumetric displacement.

With pumping solution, it is possible to keep linear performance with the rotating speed, the same volumetric displacement each rotation. And, there is no pulsation, continuous uninterrupted flow. For shear sensitive Mediums, low shear factor of all type of pumps, can handly solids particles without damage them, with High solid, high viscosity.

Especially, when producing lithium-ion battery electrode, usually select pumps to dose or meter kinds of slurry for positive pole or negative pole, including solvent series liquid and water series medium.

Analyzing Solution

In the process of making the batteries anode and cathode, the raw material is heat-treated and sintered.

Sintering is the process of heating the mixed raw material and making it into a thermosetting material. For heat treatment and sintering, it is important to understand the thermal properties of the batteries’ raw materials and active materials.

By doing a thermal analysis of active materials, thermal behavior can be identified according to the composition of each active material. For example, when the active materials reacting with active gases such as O2 and H2, the properties of active materials change. To avoid this phenomenon, there is a method of measuring thermal properties with TGA and DSC. The TGA analyzes the changes of mass under the inert gas atmospheres such as N2 and Ar in the Glove box. DSC analyzes the thermal properties of active materials by preventing the active gas reaction by sealing with a high-pressure sample fan. In addition, the gas from thermal analysis can also be analyzed by coupling GC-MS or QMS to the TGA or STA. In addition, DIL or TMA can be utilized to evaluate the sintering of the material.