Solutions

Single crystal NCM is developed for high voltage cell. It has very stable properties to high working temperature and better life cycle than normal NCM. High firing temperature is helpful to decrease the unreacted product. Remained Lithium source can make a problem, which remained LiCO3 makes the CO2 gas in the cell and remained LiOH react with solvent in mixing process, which causes the high viscosity of slurry.

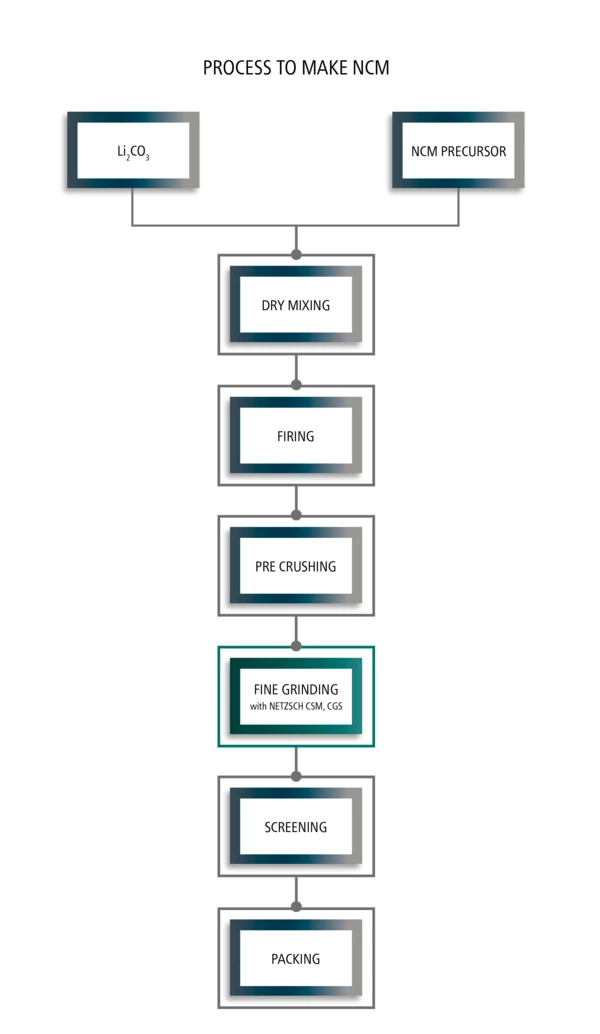

Both Wet & Dry grinding process, or sometimes only Dry grinding process, can be applied to produce cathode or anode active material. In terms of cathode material for dry grinding machines, classifying mill such as CSM can manufacture a ternary compounds cathode material such as NCM and NCA for de-agglomeration process after heat treatment process.

For example, with CSM integrated dynamic air classifier and optimized internal design, desired fineness can be achieved or simply formation of very fine particles can be avoided thru ternary compounds cathode materials. Also, Single crystal ternary cathode material NCM, NCA was developed which it is better to cycle life and higher output voltage and higher safety for the high temperature than normal ternary cathode. However, this single crystal product is more harder than normal ternary product. CSM and CGS can achieve the target fineness.

Lithium Ion Batteries (NCM, NCA…) are needed to be strengthen for its safety. Lithium-ion batteries are largely composed of a total of four elements: positive electrode material, negative electrode material, separator, and electrolyte. When the anode and the cathode are connected by conducting wires, lithium ions ride electrolytes and transfer electrons from the anode to the cathode, resulting in "discharge." Conversely, when a voltage is applied, electrons from the anode move to the cathode, causing 'charging'. The separator separates the cathode and the anode to prevent fire caused by short circuit and to pass only lithium ions. However, if this balance collapses, a fire may occur.

Therefore, stability tests must be preceded to prevent balance collapse.

Thermal Stability

Measuring the thermal diffusivity and thermal conductivity along with the specific heat capacity form the basis for comprehensive understanding. To investigate these thermophysical properties, NETZSCH offers Laser/Light Flash Analysis systems (LFA) as well as systems for Differential Scanning Calorimetry (DSC). Thermal management system failures can be avoided.

The STA 449 Jupiter® series combines configuration flexibility and unmatched performance in just one instrument. Pluggable inter-changeable DSC and TGAsensors and various furnaces allow for precise thermoanalytical measurements. By supplementary MS coupling, even more comprehensive analyses are possible.