锂电池(LiBs)电芯的主要成分

混合

搅拌混合是基础的机械设备处理工艺之一。通过搅拌,将两种或两种以上的物质混合成一种尽可能均匀的物质。

搅拌混合工艺之后通常会进行脱泡,因为从液体到高粘度产品的加工过程中,气泡通常会导致问题。气泡中的氧气会对产品产生负面影响,如氧化、酸化、变色或变味等问题。对于涂层材料,会导致表面穿孔和麻点。相比之下,脱过气泡的产品通常化学稳定性更强,更耐用。

使用行星搅拌机混合液体

用于制造阳极/阴极的涂层浆液包含许多不同的固体颗粒。这些浆料的均匀混合是电池材料工艺的主要挑战。

换句话说,浆料组分的状态决定了其物理性质,在锂离子电池的混合和涂层工艺中起着重要作用。

以下是浆料混合过程中需要解决的任务。

- 准备合适的环境

- 颗粒的加入与润湿

- 粘合剂的溶解

- 使用合适的能量解团聚

- 工艺中的温度控制

- 除气解决方案

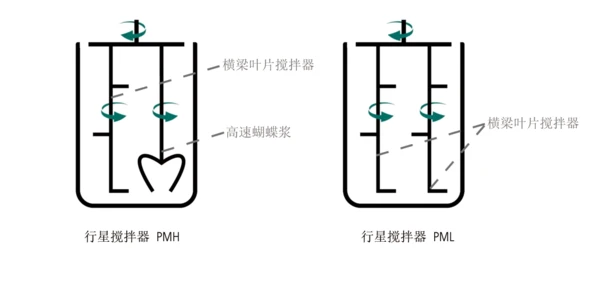

要制造LiBs电池,应在金属箔上涂上电极浆液。行星搅拌机(如PMH)用于生产电极浆液。当必须处理高粘度泥浆,特别是热敏成分时,需要用到行星混合机和捏合机。

在混合过程中,行星混合机和捏合机显示出其对非常难混合的浆液的真正潜力。

PMH适用于高粘度产品,PML是中等粘度产品的溶液。因此,换言之,由于适用于两台搅拌机的产品粘度不同,因此每个搅拌机的搅拌工具形状不同。混合元件除了自旋转外,还可以在固定容器中进行旋转运动,从而贯穿所有浆料。

Aggressive and abrasive media such as lithium are pumped safely and gently by positive displacement pumps. These pumps are used in almost all industry sectors for transporting and dosing difficult media, such as solids-bearing fluids having low to very high viscosities or even aggressive media which are used in battery production.

In battery production, the processes are also supported by pumping solution for all flow rates and pressures. For example, the NEMO® progressing cavity pumps, the TORNADO® rotary lobe pumps and the PERIPRO peristaltic pumps are used in vacuum defoaming, because slurries can be strongly suctioned even under high vacuum conditions and they are also pumping fluids in the stirring process: A variety of primary raw materials are pumped to the stirring tank and after being stirred at a high speed, the pumps will also transport them to the storage tank.

Especially, the progressing cavity pumps and the peristaltic pumps are used for applications in mixing process. Pumping liquids are Adhesive & glue, Conductive liquid & mixing slurry and Electrolyte, UV Resin or other.

In Mixing Process, the powder is mixed into the solvent. The mixture is called slurry.

It is important to understand the viscosity of the solvent or the slurry because it has different rheological properties depending on the content of them. Viscosity can be affected by the content of the powder, shear rate and shear stress. Slurry's viscosity can be measured by Rotational Rheometer (Kinexus Series).

You can also analyze Mass spectrometry or Gas chromatography with STA-QMS coupling system or the STA-GC-MS coupling system for component analysis of the solvent or the slurry.